The Ultimate Guide to Durable Metal Sheets for Various Applications

Understanding the Versatility of Perforated Metal Sheets

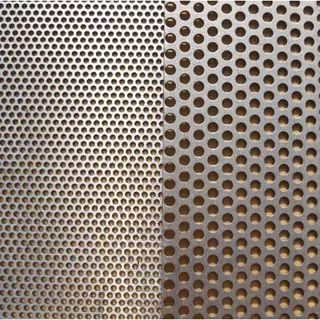

Perforated metal sheets have revolutionized various industries by offering both functionality and aesthetic appeal. These sheets, which feature a series of punched holes, are widely used in architecture, industrial applications, and even decorative purposes. One of the most durable and widely used options is the Stainless Steel Perforated Sheet, which is favored for its exceptional strength, resistance to corrosion, and adaptability across diverse environments.

From ventilation panels and soundproofing systems to stylish facades and filtration units, these sheets serve multiple purposes. The stainless steel composition ensures long-lasting durability even in challenging conditions, making it a preferred choice in marine, construction, and food processing industries. The high resistance to moisture and chemicals further solidifies its importance in applications where exposure to harsh substances is inevitable.

Why Stainless Steel Perforated Sheets Are in High Demand

A Stainless Steel Perforated Sheet stands out due to its impressive mechanical properties. It is capable of withstanding extreme temperatures, heavy loads, and corrosive environments. This makes it an ideal material for industrial enclosures, protective barriers, and even automotive components.

Moreover, these sheets are known for their aesthetic flexibility. The availability of different hole patterns, including round, square, and slotted, allows architects and designers to use them creatively in both interior and exterior designs. The ability to control light, airflow, and sound while maintaining a modern and sophisticated look makes stainless steel perforated sheets an excellent option for architectural facades, room partitions, and decorative ceilings.

Another critical advantage is sustainability. Stainless steel is fully recyclable, making these perforated sheets an environmentally friendly option. Industries that prioritize green solutions benefit greatly from incorporating stainless steel perforated sheets into their designs and infrastructure.

The Importance of Marine Grade Aluminium in Coastal and Industrial Applications

When it comes to metal materials that can withstand harsh marine environments, Marine Grade Aluminium stands out as the ultimate choice. Unlike standard aluminum, this specialized variant is engineered to resist corrosion caused by saltwater, moisture, and extreme weather conditions. This property makes it a highly sought-after material in the shipbuilding industry, offshore structures, and coastal constructions.

The primary reason for the high durability of Marine Grade Aluminium lies in its chemical composition. The inclusion of elements such as magnesium, silicon, and manganese enhances its strength and corrosion resistance. This ensures that structures and vessels made from this alloy maintain their integrity even when exposed to the relentless effects of seawater.

Apart from marine applications, this aluminum grade is extensively used in industries requiring lightweight yet strong materials. Aerospace, transportation, and defense sectors rely on marine grade aluminium for manufacturing high-performance components. Its exceptional strength-to-weight ratio ensures better fuel efficiency in aircraft, boats, and military vehicles.

How Marine Grade Aluminium Compares to Other Metals

Unlike carbon steel and regular aluminum, Marine Grade Aluminium does not succumb to rust and degradation when exposed to water. While stainless steel offers superior corrosion resistance, it is significantly heavier than marine grade aluminum, making it less ideal for applications where weight is a concern. The ability to balance durability, corrosion resistance, and lightweight properties gives this aluminum alloy a unique edge.

Another benefit is its ease of fabrication. Marine grade aluminium can be easily welded, shaped, and machined, allowing manufacturers to create complex designs and structures efficiently. This is particularly beneficial in shipbuilding, where intricate designs and structural modifications are frequently required.

Additionally, this aluminum variant has excellent thermal and electrical conductivity. In industrial setups where high conductivity is essential, such as power plants and electronic enclosures, marine grade aluminium provides a reliable solution while maintaining resilience against harsh environmental conditions.

Choosing the Right Metal for Your Needs

Both Stainless Steel Perforated Sheet and Marine Grade Aluminium offer remarkable advantages in terms of strength, durability, and resistance to environmental factors. The choice between the two depends on the specific requirements of your project.

For applications requiring high strength, corrosion resistance, and aesthetic flexibility, stainless steel perforated sheets are an excellent choice. Their ability to function as filtration media, acoustic panels, and decorative elements make them indispensable in construction and industrial sectors.

On the other hand, if you are dealing with a marine or coastal environment, or if weight reduction is a priority, marine grade aluminium is the way to go. Its corrosion resistance and lightweight nature make it a go-to material for shipbuilding, aerospace, and automotive industries.

By understanding the distinct characteristics of these materials, businesses and individuals can make informed decisions for their construction, industrial, and design needs. Whether you opt for stainless steel perforated sheets or marine grade aluminium, both materials guarantee long-lasting performance and reliability in their respective applications.

Comments

Post a Comment