Stainless Steel Perforated Sheet and Perforated Sheet Metal Explained

Stainless Steel Perforated Sheet solutions are everywhere once you start witnessing them. From industrial floors to modern edifice facades, they quietly do their job. Perforated Sheet Metal brings together strength and flexibility in a practical way. Holes aren’t a weakness here. They’re a feature. This combination allows airflow, filtration, and weight reduction without losing structural integrity. It’s functional design, not decoration for the sake of it.

What Makes Perforated Metal So Useful

Perforated Sheet Metal stands out because it solves multiple problems at once. It allows dawning, air or liquid to pass through while motionless, working as a barrier. That balance is hard to complete with solid materials. Stainless Steel Perforated Sheet options add erosion resistance to the mix, making them suitable for demanding environments. Industrial users value reliability. Creators value clean lines. Both find common ground in perforated metal solutions.

Strength Meets Precision Engineering

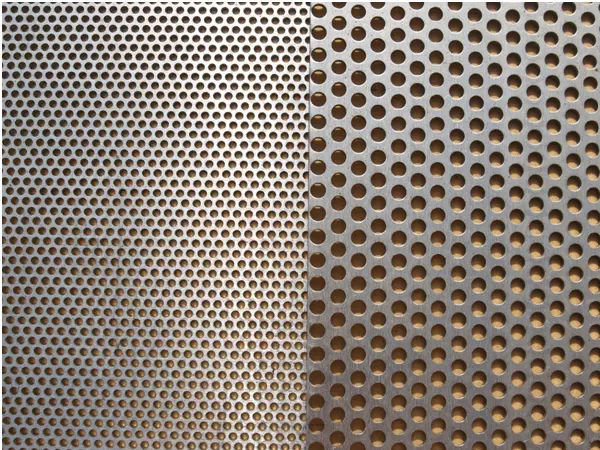

A Stainless Steel Perforated Sheet is not randomly punched metal. Hole size, pattern, and spacing are carefully calculated. These details affect strength, flow rate, and visual appearance. Precision matters. Poorly designed sheets can bend or fail under pressure. Well-made ones perform consistently over time. That’s why perforated sheet metal is trusted in safety screens, machine guards, and load-bearing applications where performance cannot be guessed or improvised.

Where These Sheets Are Commonly Used

You’ll find Perforated Sheet Metal in factories, commercial buildings, and infrastructure projects. It’s utilized in air flow panels, acoustic structures, filtration devices, and walkways. Stainless Steel Perforated Sheet textiles are particularly famous in meals processing and chemical industries due to their hygiene and erosion resistance. Outdoors, they tolerate the weather well. Indoors, they offer easy, cutting-edge aesthetics. Few substances adapt so easily throughout environments without regular maintenance.

Design Flexibility Without Compromise

Designers appreciate how flexible perforated steel may be. Different styles create specific visible outcomes without changing the base material. A Stainless Steel Perforated Sheet can look business or delicate relying on the finish and format. At the same time, it remains tough and reliable. This makes it ideal for tasks wherein appearance matters but performance cannot be sacrificed. It’s no longer flashy. It’s hopefully functional.

Long-Term Value and Maintenance

One reason Perforated Sheet Metal remains favored is its long service life. Stainless steel mutinies rust, staining and chemical damage. Cleaning is superficial. Maintenance costs stay low. Over time, that reliability adds real value. Projects run more smoothly when materials don’t need constant attention. A Stainless Steel Perforated Sheet simply does what it’s meant to do, year after year, without demanding much in return.

Conclusion

Stainless Steel Perforated Sheet and Perforated Sheet Metal products deliver a periodic mix of durability, flexibility and clean configuration. They perform well across industries without unnecessary complexity. If you’re evaluating dependable material solutions for industrial or architectural use, it’s worth exploring reliable options available through dinco.ae and choosing materials built to last.

For further info, visit our site.

Comments

Post a Comment