Enhancing Design and Functionality with Perforated Sheet Metal

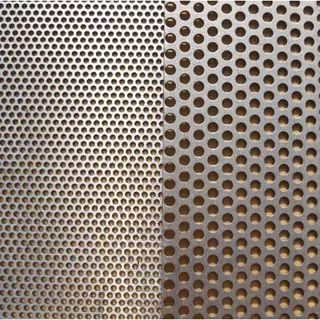

At its core, perforated sheet metal is metal that has been punctured with a pattern of holes or slots. These perforations can be customized in size, shape, and arrangement, allowing for precise control over factors such as airflow, light diffusion, sound absorption, and visibility. This adaptability makes perforated sheet metal an ideal choice for a wide range of applications, from decorative facades and sunscreens to acoustic panels and filtration systems.

One of the most prominent features of perforated sheet metal is its ability to strike a delicate balance between form and function. Architecturally, perforated metal panels can add depth and visual interest to building facades while simultaneously providing shade, ventilation, and privacy. By strategically adjusting the density and arrangement of perforations, designers can create captivating patterns that play with light and shadow, transforming ordinary structures into captivating works of art.

Beyond aesthetics, perforated sheet metal serves practical purposes in industries such as HVAC (Heating, Ventilation, and Air Conditioning) and automotive manufacturing. In HVAC systems, perforated metal sheets are used as air diffusers and ductwork components, facilitating the efficient distribution of air while minimizing noise levels. Similarly, perforated metal panels find application in automotive exhaust systems, where they enhance airflow and reduce backpressure, Aluminium Perforated Sheet thereby improving engine performance and fuel efficiency.

Moreover, perforated sheet metal plays a crucial role in environmental sustainability efforts. By incorporating perforated metal screens into building designs, architects can harness natural ventilation and daylighting, reducing the reliance on artificial heating, cooling, and lighting systems. Additionally, perforated metal panels can be integrated into rainwater harvesting systems, allowing for the efficient collection and storage of water for irrigation and non-potable uses.

In industrial settings, perforated sheet metal finds utility in filtration and separation processes. By precisely controlling the size and distribution of perforations, manufacturers can tailor perforated metal screens to capture particulate matter, separate liquids from solids, and facilitate the efficient flow of fluids. This versatility makes perforated sheet metal an invaluable asset in industries ranging from food processing and pharmaceuticals to mining and petrochemicals.

Furthermore, advancements in manufacturing technology have expanded the possibilities of perforated sheet metal design. Computer-aided design (CAD) software and laser cutting machines enable engineers to create intricate patterns and complex geometries with unparalleled precision and efficiency. This level of customization empowers designers to push the boundaries of creativity, resulting in innovative applications that blend form and function seamlessly.

Comments

Post a Comment