The Versatility and Advantages of GI Perforated Sheets

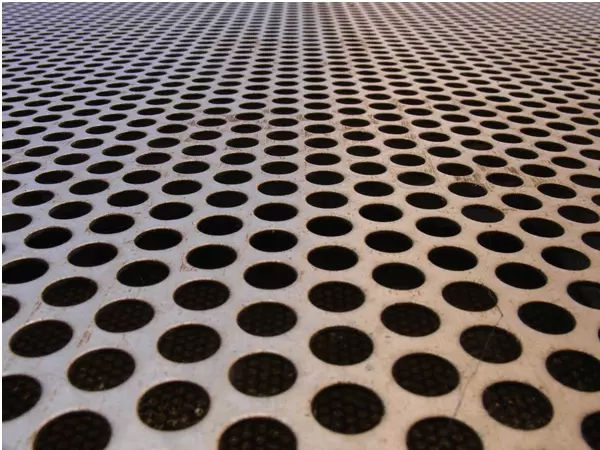

Understanding GI Perforated Sheets

A GI perforated sheet is a galvanized iron sheet that has been punctured with holes or patterns. The perforation process can produce a variety of shapes and sizes of holes, depending on the specific requirements. These sheets are available in different thicknesses and dimensions, allowing for a wide range of applications. The galvanization not only protects the sheet from environmental factors but also extends its lifespan, making it a cost-effective solution.

Applications of GI Perforated Sheets

Architectural Applications:

Aesthetic Enhancements: GI perforated sheets are widely used in architectural designs to create visually appealing facades, interior partitions, and decorative panels. The perforated design allows light and air to pass through, creating dynamic lighting effects and improving ventilation.

Acoustic Panels: These sheets are also employed in the construction of acoustic panels. The perforations help in sound absorption, reducing noise levels in various environments such as offices, auditoriums, and theaters.

Industrial Applications:

Filtration Systems: In industrial settings, GI perforated sheet are used in filtration systems for water, air, and oil. The holes in the sheets act as filters, allowing only specific particles to pass through while blocking larger contaminants.

Ventilation and Air Conditioning: These sheets are ideal for use in ventilation systems and air conditioning units. The perforations facilitate airflow while preventing the entry of unwanted debris and pests.

Agricultural Uses:

Grain Drying: In the agricultural sector, GI perforated sheets are utilized in grain drying systems. The perforations enable the even distribution of air, ensuring effective drying of grains and preventing spoilage.

Animal Enclosures: These sheets are also used in constructing animal enclosures, providing adequate ventilation while maintaining the security and safety of the animals.

Security and Safety:

Machine Guards: In manufacturing facilities, GI perforated sheets are used as machine guards to protect workers from moving parts. The perforations allow visibility and airflow, ensuring safety without compromising on functionality.

Fencing: They are also employed in fencing solutions for both residential and commercial properties. The galvanized coating ensures long-lasting protection against corrosion, Aluminium Stucco Sheet while the perforations add an extra layer of security.

Advantages of Using GI Perforated Sheets

Durability: The zinc coating provides excellent protection against rust and corrosion, making GI perforated sheets suitable for both indoor and outdoor applications.

Versatility: These sheets can be customized in terms of hole size, shape, and pattern, catering to a wide range of requirements across different industries.

Cost-Effectiveness: Due to their extended lifespan and low maintenance requirements, GI perforated sheets offer a cost-effective solution for various applications.

Aesthetic Appeal: The perforated design adds a modern and stylish touch to any project, enhancing the overall visual appeal.

Functionality: The perforations allow for effective ventilation, filtration, and sound absorption, making these sheets highly functional in diverse environments.

Comments

Post a Comment